Trust adviser

Satisfactory

AD-4976 Series

Metal Detectors

|

|

| - Inspects for metal contamination to assure safety and compliance. - User friendly 7inch touch panel operation - Multiple frequencies for better detection sensitivity of contaminants, and less false rejection by choosing the most optimizing frequency. - Available also by only sensorhead. |

|

| * Please prepare the conveyor locally for only sensor head. |

Features

![]() Protected from dust and water to IP66 standards.

Protected from dust and water to IP66 standards.

The rugged enclosure is constructed of stainless steel angled surfaces, which is ideal in sanitary reason.

![]() AND Metal Detector Measurement Environment Evaluation Tool provides stable measurement by visualizing noises around the metal detector with a frequency range set by “Auto” set in its display, and by selecting the best frequency to avoid false detection and unstable inspection.

AND Metal Detector Measurement Environment Evaluation Tool provides stable measurement by visualizing noises around the metal detector with a frequency range set by “Auto” set in its display, and by selecting the best frequency to avoid false detection and unstable inspection.

![]() Automatically, the most suitable frequency in accordance to an inspecting product is chosen among three frequencies to maximize the detection sensitivity by just feeding the product for the minimum of three times. Auto set covers wide range of products.

Automatically, the most suitable frequency in accordance to an inspecting product is chosen among three frequencies to maximize the detection sensitivity by just feeding the product for the minimum of three times. Auto set covers wide range of products.

![]() As the change in phase angle caused by temperature change is kept to a minimum, more stable inspection and inspection without warm-up are possible.

As the change in phase angle caused by temperature change is kept to a minimum, more stable inspection and inspection without warm-up are possible.

![]() AD-4976 consists of three modules: sensor head, conveyor, and frame unit.

AD-4976 consists of three modules: sensor head, conveyor, and frame unit.

Each of these are also separately available for customization to meet various type of requirements.

![]() Intuitive user interface and the high visibility touch panel color LCD enable easy operation as it is almost self-explanatory (audio guidance support function included).

Intuitive user interface and the high visibility touch panel color LCD enable easy operation as it is almost self-explanatory (audio guidance support function included).

![]() Inspection results, such as date, time, product codes and inspection results can be recorded to USB memory during inspection.

Inspection results, such as date, time, product codes and inspection results can be recorded to USB memory during inspection.

![]() Operation history, such as history configuration changes can be recorded and displayed, which is ideal for HACCP proglams along with 4 management levels control with password assigned to each user.

Operation history, such as history configuration changes can be recorded and displayed, which is ideal for HACCP proglams along with 4 management levels control with password assigned to each user.

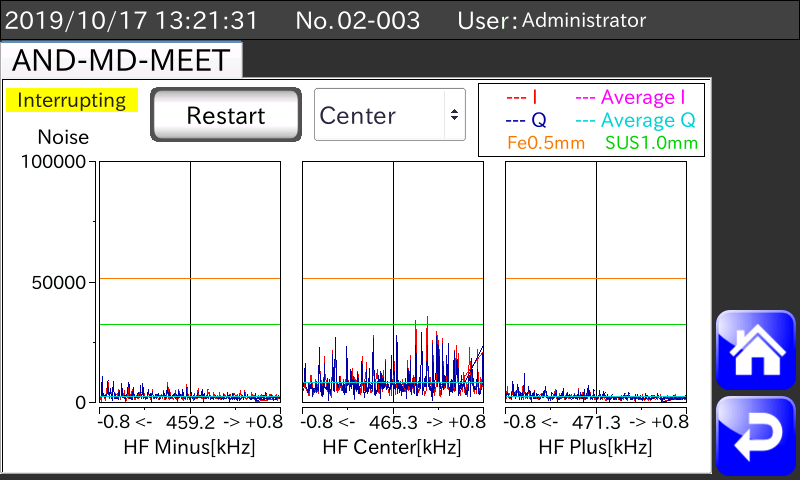

AND-MD-MEET

AND Metal Detector Measurement Environment Evaluation Tool provides stable measurement by visualizing noises around the metal detector with a frequency range set by “Auto” set in its display, and by selecting the best frequency to avoid false detection and unstable inspection. This is powerful tool when unknown cause such as randomly activating inverter is disturbing the metal detector resulting in bad performance or false detection.

Modular design

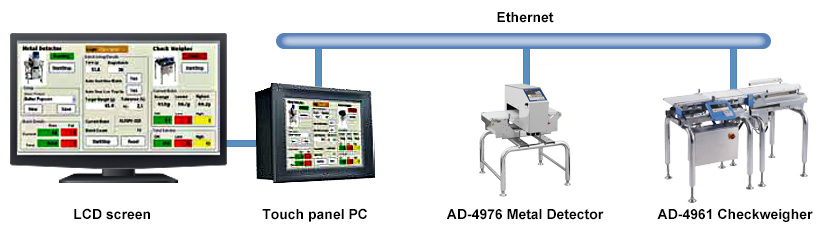

Equipped with Modbus RTU/Modbus TCP as standard. With Modbus communication, seamless connection can be easily achieved. Operations such as stopping and starting weighing, collecting data and changing product can all be set from an external device.

Specifications

| Model | AD-4976-3510 | AD-4976-3517 | AD-4976-3525 | AD-4976-4517 | AD-4976-4525 | |

| Aperture size | 350(W)x100(H)mm | 350(W)x170(H)mm | 350(W)x250(H)mm | 450(W)x170(H)mm | 450(W)x250(H)mm | |

| Pass height | Maximum 80mm | Maximum 150mm | Maximum 230mm | Maximum 150mm | Maximum 230mm | |

| Conveyor speed | 10 to 50m/min | |||||

| Carrying capacity* | 5kg(10~30m/min) 3kg(30~50m/min) | 10kg (10~20m/min) 5kg(20~40m/min) 3kg(40~50m/min) |

||||

| Number of recorded item | 1000 items including product data and image | |||||

| Communication interface | Ethernet (Modbus TCP, PostScript compatible printer) RS-232C (AD-8126 / AD-PR580 printer, AD-4961 Weight Checker product number sharing) RS-485 (Modbus RTU) USB (USB flash drive, history storage, image source and PostScript compatible printer) |

|||||

| Dust / water resistance specifications | IP66 | |||||

| Material | SUS304 | |||||

| Diameter of conveyor rollers | 33mm | |||||

| External input | Non voltage contact input 4 | |||||

| External output | 6 ( 2 for rated 30 VDC / 250 VAC 10A, and 4 for rated 60 VDC 0.3A) | |||||

Note

*These values are dependent on the inspected items and/or environments where the AD-4976 is used.

For further details, please consult with your sales staff.