| AD-4961 Series |

| Checkweighers |

|

|

| Best-in-class precision |

With a newly developed digital load cell and an ultra-high speed processing module, high level precision of 0.08g (3σ)*1 has been realized.

With this high accuracy checkweigher, you can minimize the giveaway of materials above the specified weight and contribute to reductions in production costs. |

| *1 For AD-4961-2KD-2035. Depends on the shape and the condition of the product and installation environment. |

| 7 inch color touch panel |

| The display utilizes a high visibility touch panel color LCD with user friendly Graphic User Interface (audio guidance support function included). |

| Image import from USB |

| Product images can be quickly uploaded to the checkweigher from a USB flash drive, making product identification and upload fast and simple. |

| IP65 |

| Protected from dust and water to IP65 standards. Hygienic design with the entire system washable. |

| Stores up to 1000 products |

| Products can be divided into 10 different groups, with up to 100 products able to be recorded within each group. |

| Lightweight and compact design |

| With its modular structure, the AD-4961 allows for rapid and simple installation or relocation. |

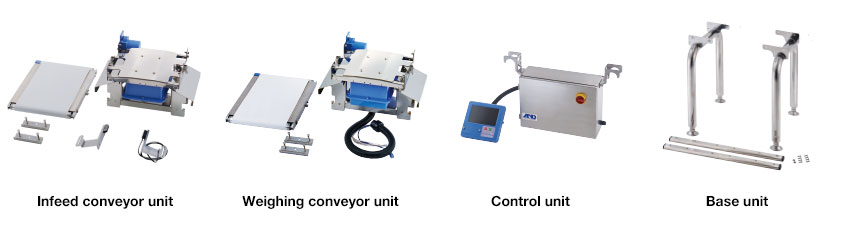

| Unique modular design |

AD-4961 consists of four units: an infeed conveyor unit, a weighing conveyor unit, a control unit and a base unit, allowing fast and simple assembly.

In the case of system shutdown, you do not need to wait for a service engineer to respond to the issue.

Just simply replace the unresponsive module by yourself, so that you can shorten system downtime and maximize production efficiency. |

| Optimization of weighing configuration |

By inputting throughput (products per minute) or belt speed (m/min), optimal weighing conditions can be automatically set.

You can weigh products precisely without inputting various settings. |

History function

Operational history

|

The history of configuration changes can be recorded and displayed. Suitable for use in HACCP programs along with the weighing history function.

Users can be registered and their scope of permitted operations controlled according to 4 management levels.

[ Operation ]

[ Supervisor ]

[ Quality Manager ]

[ Administrator ]

By assigning each user to the appropriate level of access, inadvertent operations can be avoided.*2

*2 "Operator" is set as the factory default setting. |

|

Weighing history

|

Weighing results are automatically recorded in a USB flash drive during weighing.

Output data: Date, time, group and product number, weight data and judgments.

USB memory

Approx. 6MB memory size is required for 8 hours operation at the maximum throughput (320pcs/min.)

Approx. 7GB memory size is required for 24hours 365days operation. |

|

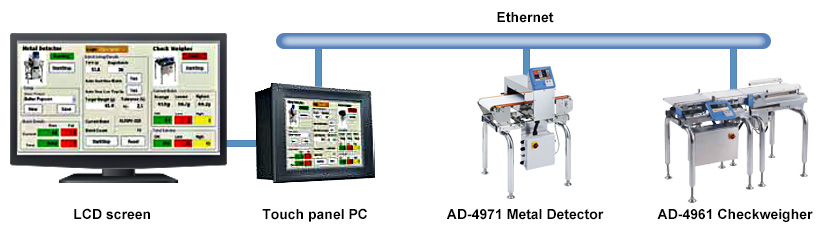

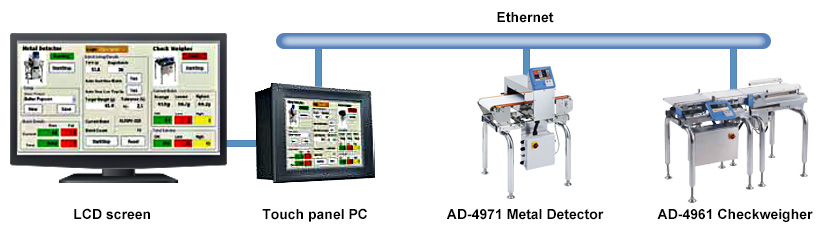

| Modbus communication |

Equipped with Modbus RTU/Modbus TCP as standard.

With Modbus communication, seamless connection can be easily achieved.

Operations such as stopping and starting weighing, collecting data and changing product can all be set from an external device. |

| Various inputs / outputs |

Rejector output , alarm output, metal detector input, RS-232C, TCP/IP and USB interface are equipped as standards.

Storing data in a USB flash drive or outputting to a printer are also possible. |

| Graph printing to a printer |

| Histogram, X/R control charts and summary reports can be outputted to a PostScript printer via Ethernet. |

| Data summary |

Various summary data such as histograms (frequency including defects), X charts, R charts, total summaries, etc., are available.

You can visually confirm fluctuation of weighing results and adjust your manufacturing machine accordingly. |

Histogram, control charts and summary reports

After weighing, press the PDF key on the summary display. A PDF report is outputted to a USB flash drive.

The same reports can be printed out by pressing the PRINT key when a PostScript printer is connected to the checkweigher.

Histogram printing example  |

Control chart printing example  |

Summary results printing example  |

| USB memory function |

Weighing history and operation history are stored in a USB flash drive.

You can also output histogram, X/R control charts or summary data to a USB flash drive in PDF format.

A USB flash drive needs to be inserted before weighing. |

| *Please prepare a USB flash drive. |

| Specifications |

| Model |

AD-4961-600-1224 |

AD-4961-2KD-2035 |

AD-4961-6K-3050 |

| Capacity |

600g |

500g / 2,000g |

6,000g |

| Resolution |

0.01g |

0.01g / 0.1g |

0.1g |

| Accuracy(3δ) *1 |

0.08g |

0.08g / 0.18g |

1.0g |

| Max. throughput |

400 pcs/min |

320 pcs/min |

145 pcs/min |

| Conveyor belt width |

120mm |

200mm |

300mm |

| Conveyor length |

Infeed 360mm, Weighing 240mm |

350mm |

500mm |

| Transport medium |

Urethane belt |

| Conveyor belt speed |

15~120m/min |

10~80mm/min |

| Max. product dimensions |

Length : 22~200mm

Width : 120mm |

Length : 30~300mm

Width : 200mm |

Length : 80~450mm

Width : 300mm |

| Weighing sensor |

Strain gauge load cell |

| Display |

7 inch touch panel color display (WVGA) |

| Operation method |

Touch panel (resistive film type), operation buttons |

| Number of recorded items |

1,000 items (10 groups x 100 items) |

| Communication functions |

Modbus TCP / Modbus RTU / RS-232C/485 (selectable) / TCP/IP (PostScript printer)

USB (for PostScript printer, USB memory, data storage, image import use) *3 |

| External input |

Non-voltage contact input 4 points |

| External output |

Relay output 8 points |

| Dust/water resistance specifications |

IP65 |

| Operation temperature/humidity range |

-5~40℃ / humidity below 85% (with no condensation) |

| Power supply *4 |

Single phase AC100V-240V (+10% / -15%), 50/60Hz 180VA |

| External dimensions *2 |

Length : 606mm

Width : 662mm

Height : 713-863mm |

Length : 700mm

Width : 660mm

Height : 710-860mm |

Length : 1005mm

Width : 736mm

Height : 720-870mm |

| Weight *2 |

Approx. 35kg |

Approx. 50kg |

| Material |

Display : ABS resin

Conveyor unit : Aluminum (alumite coating) and PP resin

Control box : Stainless steel

Base unit : Stainless steel |

*1 Depends on the shape and the condition of the product and installation environment.

*2 Values for external dimensions and weight are for standard conditions without rejector.

*3 USB memory must be formatted to FAT32.

*4 Please prepare a Φ4-7mm power cable. |

| Accessories |

|

|

|

| AD4961-01Display stand |

AD4961-02Tower light |

AD4961-11Upper breeze break |

The display is attached on the opposite side from the standard display position, across from the user.

The display is located approx.

310mm above the conveyor belt. |

Highly visible three color LED tower light.

Easy configuration with the AD-4961 checkweigher using DO (Digital Output) map setting.

*AD-4961-01 display stand is required to install this option.

*Dust and water resistance level is IP53. |

Anti-static breeze break prevents air currents to the weighing conveyor and static electricity to achieve accurate weighing.

Clearance between the conveyor belt and the breeze break is 135mm.

Use together with the lower breeze break is recommended.

Material : PVC anti-static plate

*This option is for AD-4961-2KD-2035. |

|

|

|

| AD4961-12Lower breeze break |

AD4961-13Cross plate |

AD4961-14Product guide |

Prevents air currents from underneath the system to ensure accurate weighing.

Use together with the upper breeze break is recommended.

Material : Stainless steel

*This option is for AD-4961-2KD-2035. |

Eliminates gap between infeed conveyor and weighing conveyor and conveys products smoothly.

Suitable for weighing small products.

Material : Stainless steel

*This option is for AD-4961-2KD-2035. |

Installed on both infeed and weighing conveyors.

Adjusts products to be conveyed on the center of both conveyors.

Applicable product width is from 50mm to 100mm.

Material : Stainless steel

*This option is for AD-4961-2KD-2035. |

|

|

|

| AD4961-11-1224Anti-static breeze break |

|

|

Length: 320mm, Width: 263mm

Three stage pass height adjustable:

60mm, 105mm, and 150mm

Material: PVC anti-static plate

*This option is for AD-4961-600-1224 |

|

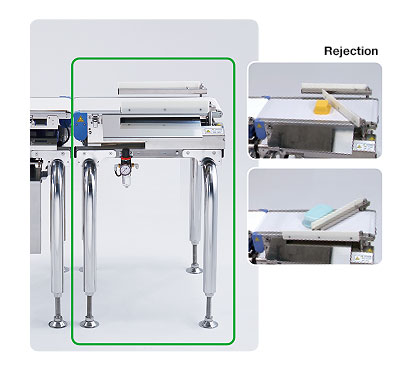

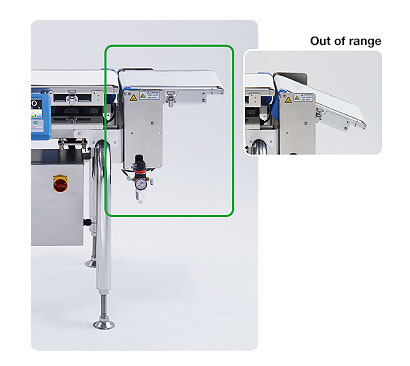

Rejector for AD-4961-2KD-2035 and AD-4961-600-1224

|

| Model |

AD-4984-1246 |

AD-4984-2046 |

| Conveyor belt width |

120mm |

200mm |

| Conveyor length |

460mm |

| Screening capacity*1 |

400pcs/min |

320pcs/min |

| Air supply*2 |

0.5MPa, 2.4NL/time |

*1 Depends on the shape and the condition of the product and installation environment.

*2 Please prepare an air compressor with a Φ10mm air tube to be connected to the filter regulator of the rejector. |

| AD-4984-1246/2046Air jet rejector |

| Rejector for AD-4961 Series |

|

|

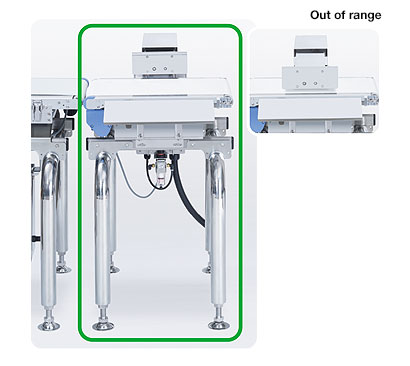

| AD-4981-2057Flipper type rejector |

AD-4982-2035Conveyor drop rejector |

|

| Model |

AD-4981-2057 |

AD-4982-2035*3 |

| Conveyor belt width |

200mm |

200mm |

| Conveyor length |

570mm |

350mm |

| Screening capacity*1 |

120pcs/min |

150pcs/min |

| Air supply*2 |

0.5MPa, 0.2 NL/time |

0.5MPa, 0.3 NL/time |

*1 Depends on the shape and the condition of the product and installation environment.

*2 Please prepare an air compressor with a Φ6mm air tube to be connected to the filter regulator of the rejector.

*3 When connecting the rejector (AD-4982-2035) to the AD-4961-600-1224 or AD-4961-6K-3050, base unit (AD-4982-11-79) is required.

Rejector for AD-4961 Series

|

AD4983-3050Pusher rejector |

| Model |

AD-4983-3050 |

| Conveyor belt width |

300mm |

| Conveyor length |

500mm |

| Screening capacity*1 |

60pcs/min |

| Air supply*2 |

0.5MPa, 2.6 NL/time |

*1 Depends on the shape and the condition of the product and installation environment.

*2 Please prepare an air compressor with a Φ8mm air tube to be connected to the filter regulator of the rejector. |

| Unit supply for AD-4961-2KD-2035 |

| We supply checkweigher modules individually, allowing you to build a weighing system which fits your production lines. |

|

|

|

| AD-4961-2K-WUWeighing unit |

AD-4961-2035-MOBMotor base unit |

AD-4961-2035-WCVWeighing conveyor unit |

High accuracy digital output module.

Stopper mechanism protects the load cell from overload.

Easy connection to the AD-4961-CNT control unit.

Dust and waterproof to IP65.

Motor cable included. |

Motor base unit for 200mm width conveyor belt.

Motor unit is pre-installed.

Dust and waterproof to IP65 when used with the AX-KO4223-080 cable.

2 sets are required for the infeed conveyor and the weighing conveyor. |

A conveyor unit with balance adjusted pulleys enables accurate weighing.

*Different from the infeed conveyor unit. |

|

|

|

| AD-4961-DISPColor touch panel display unit |

AD-4961-CNTControl unit |

AD-4961-INFInfeed unit |

7 inch color touch panel display with a USB memory port.

Easy connection to the AD-4961-CNT control unit. |

Water and dust proof to IP65.

Communication functions:

Modbus TCP / Modbus RTU (RS485) / RS232C / RS485 (selectable) / TCP/IP for PostScript printer / SB (USB memory for storing data, capturing images and connection to a PostScript printer.)

Base functions:

Item registration: 1000 items

Non-voltage inputs: 4 points

Relay outputs: 8 points

Power supply: Single phase AC100-240V

Load cell connection:

Please use the AD-4961-2K-WU |

Conveyor height can be adjusted with this unit. |

|

|

|

| AD-4961-UFAttachment brackets |

AD-4961-2035-ICVInfeed conveyor unit |

AD-4961-2035-FPBase unit |

Attachment brackets to fix the infeed unit and weighing unit.

*2 sets are required for the infeed unit and the weighing unit. |

*The pulleys for the infeed conveyor unit are not balance adjusted.

The conveyor belt is different from the one for the weighing conveyor. |

Consists of feet and side beams.

2 sets of AD-4961-UF are installed on the base unit. |

|

|

|

| AD-4961-81-2KPhoto sensor with attachment |

AD-4961-80-2KAttachment for the display unit |

AX-KO4223-080Motor cable for the infeed conveyor |

|